Read the Fibre Direction: A Guide to Lint-Free Cutting of Cardboard, Paperboard and Corrugated

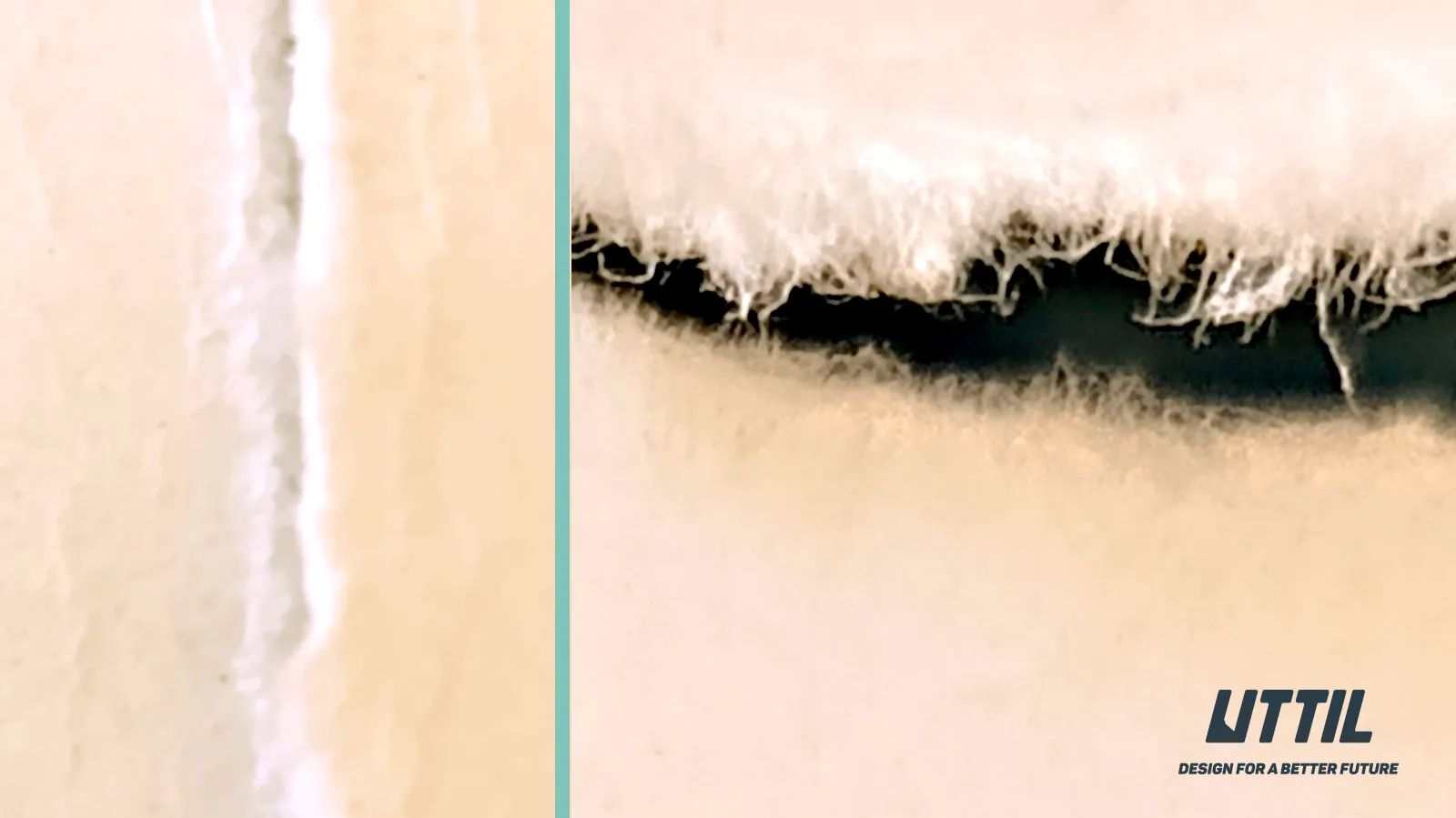

The edge quality of cardboard, paperboard and corrugated

board often depends on how you manage the fibre direction before the

knife. Correct alignment reduces "feathering", limits tearing and

reduces waste. The following practical framework can be quickly implemented in

everyday workshops and packaging work.

1) Quickly "read" the fibre

orientation

- Cardboard:

It

is usually sufficient to gently bend one edge in two directions. The

direction that bends easily is often considered to be the MD (Machine

Direction); the relatively resistant side is considered to be the CD

(Cross Direction - the direction perpendicular to the MD). In a simple

tear test, the tear is flatter along the MD and more "hairy" on

the CD.

- Corrugated

cardboard: The

direction of the flutes is an important clue. When cutting parallel to the

corrugations, the blade runs more smoothly; when cutting perpendicularly,

fibre breaks and tears may be more pronounced.

Ergonomics Tip: Aligning

critical cutting lines parallel to the MD as much as possible when

placing parts reduces both labour and blade consumption.

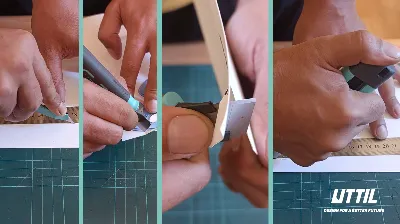

2) "Scoring → deepening" approach

Especially

when cutting in the CD direction, going deeper in one step can increase edge

distortion. First, the cutting line is stabilised with a very light pass (scoring)

and then the cut is gradually deepened and completed in 1-2 steps.

- In

cardboard and paperboard, this method ensures a clean cut without

breaking the fibres.

- In

corrugated cardboard, especially when working perpendicular to the flutes,

scoring reduces breakage on the outer surface.

3) Ruler and angle adjustment: Line

management

- Metal

ruler +

non-slip base stabilises the line.

- When

the blade comes to the surface at about 10-20°, the cutting edge

"cuts" the fibres; at higher angles, the pubescence is reduced.

- For

long lines, fixing the ruler to the body side helps to limit

deviations.

Note: A flat, non-stretch cutting

mat improves edge integrity, especially in corrugated board, by preventing

voids from forming under the flutes.

4) Short strategy guide for material

- Cardboard

(single layer): Lines

parallel to the MD give smoother results. For CD cuts,

first use light scoring and a low angle.

- Cardboard

(multi-ply): There

is a tendency for delamination at layer transitions. Multiple light passes

and pressure with a metal ruler control layer "slippage".

- Corrugated

cardboard:

- Parallel

to corrugations: Light pressure and a long, flowing motion provide a

clean edge.

- Perpendicular

to the grooves: Scoring + gradual deepening + low angle reduces

surface "pop".

- Coated

surface detail: Starting the cut on the side with the pressure and/or

coating significantly

reduces tearing and coating lifting at the point where the blade emerges on

the opposite side.

5) Blade, blade and mechanism selection

- Snap-off

blade: When

the blade is blunt, the segment is broken off to produce a fresh blade

immediately, making it efficient for fine work at 9 mm and long lines at 18 mm.

- Blade

geometry: 30° tip in detail; TiN-coated segments stay sharp

longer for a long series of cardboard-corrugated cuts.

- Locking

preference: Screw clamping bodies increase blade stability on long and

deep lines; automatic locking adds speed on flowing jobs.

- Parcel

cutting & thick corrugations: Trapezoidal/hook inserts cut tape

and thick corrugations in a controlled manner; PRUK06 (with automatic

retraction) supports safe and fast work on these jobs.

Product matches from UTTIL:

- Precision

lines (cardboard): PTUK07-30 (9 mm, 30° tip)

- Long

lines/stability and deep cutting: VMUK coded series (screw lock, 18

mm)

- Serial

groove cuts: PTUK08-EX (18 mm, TiN-coated grizzly horse)

- Fluent

general use: NMUK09 (18 mm, ergonomic HIPS+TPE housing)

- Parcel

cutting / dense packaging: PRUK06 (trapezoidal/hook bit, automatic

retraction)

6) Planning habits that reduce waste

- Layout:

Position

the parts so that the critical lines are aligned with the MD.

- Marking: Marking MD/CD

with a small arrow on the back of the cutting material can speed

up repetitive work.

- Sample

cutting: Testing

the angle-print-pass combination on a small piece of a new type of

board/cardboard eliminates most errors in the first place.

7) Without compromising safety

Routing

the line away from the body, carrying the blade closed/locked outside

of work, and replacing blunted blades in a timely manner increase confidence as

well as control.

Conclusion

What makes the

difference in edge quality is not only the right blade, but also the correct

management of the MD / transverse CD direction. "Locking" the

line with scoring, gradual deepening at a low angle and clever positioning of

the ruler result in cleaner edges and less waste.