Anatomy of the Human Hand: A Mini Guide for Hand Tool Users

The hand makes both powerful

and precise movements possible through the harmonious operation of bones, muscle-tendons,

nerves and sensors (receptors that detect touch) at the fingertips. The

following brief tour summarises the basic biomechanics behind the control you

feel in everyday life by adding scientific terms alongside simple explanations.

1) Skeleton: 27 parts

"carrier" architecture

A hand

has eight carpal (wrist bones), five metacarpals (palm bones)

and 14 phalanges (finger bones). This structure transfers force from

the wrist to the tips of the fingers efficiently while allowing agile movements.

2) Muscle-tendon duo:

Power work and fine work

The muscles

of the hand are considered in two groups: extrinsic muscles (muscles starting

in the forearm, whose tendon extends to the hand and produce more than a "large

force") and intrinsic muscles (originating from the hand, fine-tuning and positioning of the fingers and small muscles). This division of labour

enables both the generation of power when cutting thick cardboard and power

production, as well as precision when managing millimetre curves in a model.

3) "Reel" system:

A2 and A4's critical role

On the inner face of the finger flexor tendons

(rope-like structures that serve to flex the fingers and transmit

muscle power to the fingers), pass through annular pulleys (ring-shaped

ligament bands) called tunnels. In particular, A2 and A4 pulleys

(the two most important pulley bands) hold the tendon close to the bone,

reducing the risk of bowstringing (spring beam-like popping out);

thus, minimising the loss of power in grip.

4) Thumb magic: Opposing

resisting (opposition)

The CMC

joint (trapeziometacarpal; the main multi-directional joint of the

thumb) at the base of the thumb enables opposition (the thumb opposing

the other fingers) to occur. This movement provides a large part of the precise grip and secure grip.

5) Grip types: Power or

precision?

The

classic classification distinguishes two basic strategies: power grip (high-force grip, where the fingers press the palm) and precision

grip (grip where the thumb-index/middle finger triad

adjusts the position with small forces). In everyday work, these two strategies

become fluidly intertwined.

6) Finger tip "sensors":

Mechanoreceptors (sensors for touch and mechanical stimulation)

in the skin, Meissner bodies (slight contact and sliding on

the surface), Merkel cells (constant pressure and edge differentiation),

Pacini bodies (high frequency vibration) and Ruffini end organs

(skin stretching and shape change). This network enables instantaneous adjustment

of the gripping force; it helps to run the blade over the line without pressing

more than necessary.

7) Friction, moisture

and "wrinkled finger" effect

Skin hydration (skin

moisturisation level)

modifies finger-surface friction and the slip threshold. Finger wrinkling

(temporary wrinkling of the skin surface ), seen after exposure to water,

can reduce the grip force required when holding wet objects; i.e. increase efficiency.

8) Nerve network: Median-Ulnar-Radial

triad

Sensory and motor control of the hand; median

nerve ( sensitive movement and sensation around the thumb-index and index finger

). It is provided by the ulnar nerve (the line that runs most of

the intrinsic muscles on the side of the little finger ) and by the

radial nerve (especially the hand dorsal sensory and finger extensor muscles).

This "wiring" coordinates the power-sensitivity balance.

Ergonomics Tip Boxes

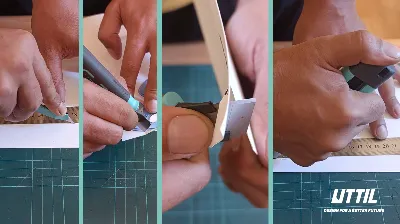

- Precise

cutting:

Holding your wrist straight and bringing the blade close to the surface at

an angle of about 10-20° to the surface can create smoother lines in

one pass without going deeper in several slight passes.

- Long

line:

The use of a metal ruler and preferably a non-slip base increases

line continuity; fixing the ruler to the side of the body reduces unwanted

escapes.

- Grip

confidence:

Dry/sweaty hands, or gloves with TPE-coated bodies (e.g., MUK09 / VMUK09)

can reduce slippage by increasing friction.

- Blade

maintenance: Snap at the blunted segment at the tips safely breaks; at the trapezoidal tips, if blunted, immediately replace them to improve the quality

of cut and safety.

UTTIL & Connection with Mozart: Reflection of Science into Product

- Grip

and friction: NMUK09 / The HIPS body TPE + sheath on the

VMUK09 supports control (pen/pinch) and power grip.

- Choice

of mechanism: NMUK (automatic lock) for fast use in smooth work;

VMUK (screw clamping) for long lines for those who want to adjust

the blade stability manually.

- Blade

character (pocket types): PTUK07 (9 mm) and PTUK08 (18 mm)

families standard, 30° precision, segmentless and TiN-coated variants make it easy to choose the power-precise balance that

the job requires.

- Trapezoidal

applications:

PAUK06 (3-stage blade output) and PRUK06 (automatic

retraction) with "trigger-like" grips offer rhythmic and safe

advancement in warehouse/packaging processes.

- Sharpness

standard:

Mozart Blades (Solingen); 9 mm/18 mm snap-off, 30° precision, TiN coated,

segmentless and trapezoidal/hook blade options produce clean and

repeatable cuts.

Quick Selection Table

|

Business / Scenario |

Recommended grip |

Suitable UTTIL model(s) |

Tip/Knife recommendation (Mozart) |

|

Model -

typography - template |

Pencil or Pinch |

NMUK09, PTUK07-30, |

9 mm 30° precision snap-off, P1 and P2 blades |

|

Thick cardboard

- long box disassembly |

Power + Ruler |

NMUK09, NMUK04/05 |

18 mm snap-off / TiN

(long life, ease of friction) |

|

Narrow

area - mobile fast intervention |

Pinch |

PTUK07-SS, PTUK07-30 |

9 mm snap-off (standard or 30° precision) |

|

Warehouse/packaging

- series segments |

Trigger style |

PAUK06

/ PRUK06 |

Trapezoid / Hook end |

|

Deep and

smooth channel (single piece) |

Power |

VMUK03/04/05/09 |

Segmentless knife |

Short Security Summary

- It

is generally safer to make cuts away from the

body.

- Turning

off

the blade or locking it, or when the work is finished, reduces the possibility of accidents.

- Keeping

the working surface flat, dry and non-slip increases the feeling of

control.

- It

is recommended to accumulate the snap-off segments in a safe container and replace them immediately when the trapezoidal tips become

blunt.

- When

using the PRUK06, seeing the blade automatically retract at

the end of the cut provides an added level of safety.

Scientific Sources (Openly)

1. Standring S. Grey's Anatomy: The Anatomical Basis of Clinical

Practice. 42nd Edition. Elsevier; 2020. (basic reference for bones and joints

of the hand).

2. Moore KL, Dalley AF, Agur AMR. Clinically Oriented

Anatomy. 8th Edition. Wolters Kluwer; 2018. (Anatomy of the upper extremity

and hand).

3. Orthobullets. Flexor Pulley System - Hand. (Clinical and biomechanical importance of A2-A4 pulley structures and the bowstringing concept.)

4. Bosco F. Closed flexor pulley injuries: a literature review.

Orthopaedic Reviews. 2022;14(1).(Pulley injuries and function.)

5. Napier JR. The prehensile movements of the human hand.

J Bone Joint Surg Br. 1956;38-B(4):902-91313. (The classic source of the

power-sensitive grip classification.)

6. Abraira VE, Ginty DD. The sensory neurons of touch. Neuron. 2013;79(4):618-639. (Mechanoreceptor Types and Physiology of Touch)

7. Kareklas K, Nettle D, Smulders T. Water-immersion finger-wrinkling improves handling of wet objects. PLOS ONE. 2013. (Wrinkled fingers and grip efficiency.)