Grip Atlas: Ergonomics and Controlled Cutting with UTTIL

Achieving the correct result when cutting is not only about selecting the right knife, but also about how it is used. The proper grip and angle contribute to working with less effort, cleaner lines and greater confidence.

This mini guide offers practical and easy-to-apply

ergonomic recommendations for everyday use within the UTTIL product

family.

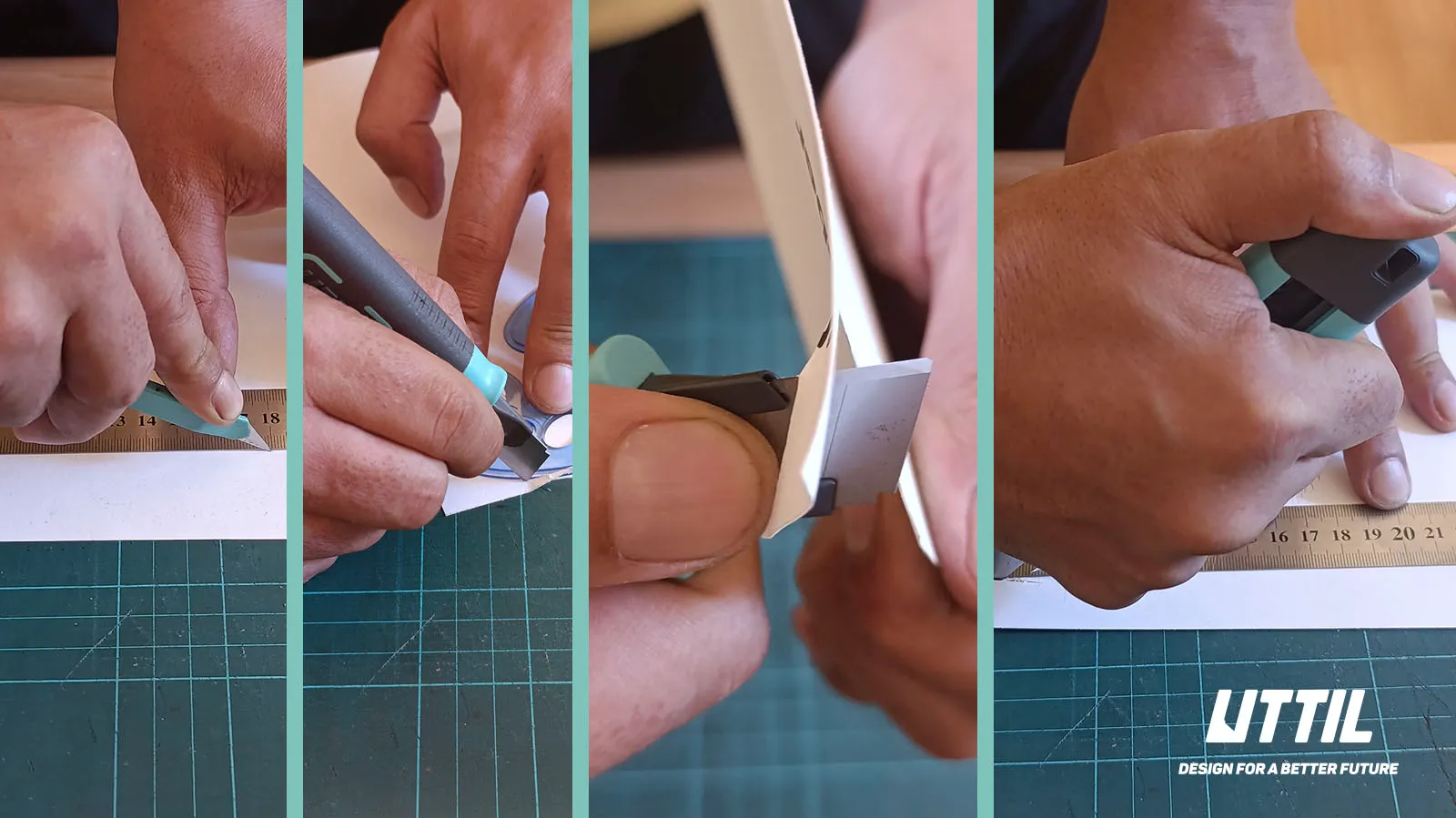

1) Four basic grips: Which one when?

A. Pencil grip

When to use: For

short, controlled lines such as model details, template cuts, paper carving and

typography.

How does it feel? A

balanced grip guided by the thumb and index finger; control increases when the

wrist remains parallel to the line and in a natural position.

Examples from UTTIL: NMUK09

/ VMUK09 (HIPS body + TPE cover, finger rests) can provide a secure grip

for fine work. PTUK07 family, especially PTUK07-30 (9 mm, 30° tip), can

be preferred for precise cutting.

Examples from Mozart Blades: The Mozart Blades P1A and P1T

models, featuring a metal body, TPE coating, and finger support, provide a controlled

grip for fine work.

B. Power grip

Suitable for:

Long, steady cuts in corrugated cardboard, thick cardboard and Styrofoam-like

materials. It is necessary for cutting relatively hard or dense materials.

How does it feel?

When the body is gripped with the palm and moved forward at a narrow angle, line continuity is easier. Continuing the cut by increasing the cutting depth

in several passes gives a more controlled result. It is crucial for safety that

the blade is segmented and the single segment is open in this type of cutting. For cutting deep and thick materials with a power grip, it is recommended to use segmentless blades or trapezoidal blades that match the desired cutting depth.

Examples from UTTIL: VMUK09

(screw-lock) increases stability in long and deep lines with a segmentless

blade. NMUK04 / NMUK05 helps reduce pressure with its metal body weight.

PAUK06 features a trapezoidal blade, enabling plunge cutting and power

grip for both hands, and can be equipped with a hook blade if required.

Examples from Mozart Blades: Mozart

Blades S2 and EVO models offer the best results for power cutting

applications, such as thick floor coverings, thanks to their metal bodies,

weight, and ergonomic design.

C. Pinch grip

Suitable for:

Precise cuts requiring direction changes over short distances, manoeuvring in

tight spaces, and scraping cuts (e.g., when trimming leather material or

cleaning edge burrs).

How does it feel?

Movements of the wrist or elbow direct the balance established by pinching

between the thumb and index finger.

Examples from UTTIL: PTUK07

and PTUK08 family (pocket type, 9 and 18 mm) offer agile use in confined

spaces. The TPE surface on the NMUK09 can provide reliable grip even when hands are sweaty.

Examples from Mozart Blades: The Mozart Blades P2A and P2T models, featuring a flat metal body and TPE coating, provide a controlled and secure grip for tasks that require a pinch grip.

D. Trigger grip

Suitable for:

Rhythmic, serial cuts such as box dismantling, intensive packaging work and

warehouse operations, as well as cutting insulation materials, providing a firm

grip and cutting ability, especially with hook blades.

How does it feel?

Placing the index finger on the trigger protrusion under the body and

positioning the thumb on top of the body allows the body to be placed in the

palm, providing a strong and controlled cutting action. For safety, it is

imperative to ensure that the wrist remains straight, the flow is unobstructed, and your body is positioned outside the cutting line.

Examples from UTTIL: PAUK06

(trapezoidal blade, three-stage blade release) and PRUK06 (trapezoidal

blade, automatic retraction) are compatible with this grip, as both models have an architecture suitable for use with either the right or left hand.

2) Right/left hand and blade direction

- In

the PTUK07 family, the blade direction can be

changed, which helps to see the line more comfortably when working with

the left hand.

- PAUK06

/ PRUK06 body structure can be used equally with

both hands and is designed to maintain safe cutting, especially when

gripping the trigger.

- NMUK09

/ VMUK09 and other 18 mm bodies offer a natural

grip for the hand; features such as back teeth and TPE surfaces enhance

grip safety.

- Screw-tightened

(VMUK series) models provide the ability to adjust

blade stability and length, particularly when working on long or deep

cutting lines.

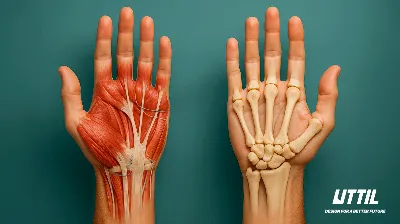

3) Gloves, wet surfaces and friction

- Use

of gloves: Nitrile or PU-coated gloves can

generally improve grip. Excessively slippery palm surfaces should be

avoided as they can reduce control.

- TPE's

contribution: UTTIL NMUK09 / VMUK09 or

Mozart Blades S2, P1, and P2 series feature a TPE coating that

increases the friction surface, providing a safer grip whether used with

gloves or on dry or slightly sweaty palms.

- Wetness:

Drying the handle and the hand that will grip the knife before cutting

helps improve cutting control.

4) Line management: ruler/guide and wrist

angle

- Scoring

(lightly scratching the surface): When the knife is

brought close to the surface at a slight angle of approximately 10–20°,

a smooth line can be achieved with a few light passes.

- Long

lines: A metal ruler and preferably a non-slip

base support line continuity. Securing the ruler and not directing the

blade towards the body during cutting reduces unwanted accidents.

- Corner

turns: Small, controlled movements of the

wrist, combined with a pinching grip, contribute to smoothness in turns.

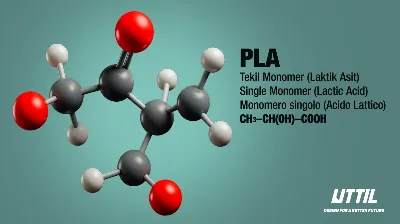

5) Blade selection and practical maintenance

(with Mozart)

- Snap-off

blades: When the tip becomes blunt, breaking

off the segment safely helps maintain cutting quality. The break-off slot

in the steel clips of the PTUK07 and PTUK08 series makes this

process practical. For all other models, we recommend using pliers or a

similar tool to break off the blade segments for safety reasons. Never

force the tip to break uncontrollably, or attempt to break it by pressing

it firmly against a workbench or flat surface.

- Segment-free

(full) blade requirement: The VMUK series (screw-lock and single-piece blade models) is more suitable for deep and

smooth cuts.

- Trapezoidal

blades: The three-stage adjustable blade exit

in the PAUK06 allows for stage and control according to different

materials. The automatic retraction mechanism in the PRUK06 helps reduce

accidents at the end of the cut, enabling safer cutting.

- Mozart

Blades: All UTTIL models are compatible

with Solingen-made Mozart Blades, which offer 9 mm/18 mm snap-off,

30° precision tips, TiN coating and trapezoidal/hook options for clean

and continuous cuts.

6) Short safety summary

- Cutting

away from the body is generally safer.

- Closing

or locking the blade when the job is done can help reduce the risk of

accidents.

- Keeping

the work surface flat, dry, and non-slip enhances control.

- Collect

snap-off segments in a safe container. It is recommended to replace all

dull cutting tips with sharp ones as soon as possible.

The right UTTIL model, combined with the appropriate grip, can enhance the cutting experience by reducing effort, producing cleaner lines, and increasing confidence. Pen grip for precision, power grip for stability, pinch grip for manoeuvrability, and trigger grip strength in trapezoidal blade models; the ergonomics of UTTIL bodies and the cutting quality of Mozart Blades combine to deliver better results.