Snap-Off Blades: Are They the Superior Choice for Your Utility Knives?

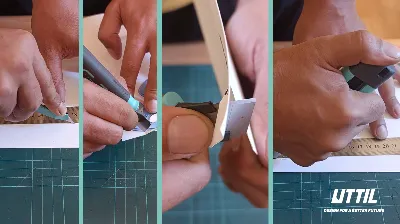

In the world of hand tools, the utility knife is a versatile and essential

tool for tasks ranging from opening boxes to precision cutting in handcrafts.

The most crucial development in this field is the snap-off blades. But is this

a better solution for your utility knife needs?

The Rise of Snap-Off Blades

Snap-off blade technology, first introduced in the 1950s, brought a novel

solution to a common problem – maintaining a sharp edge on a utility knife. The

design consists of a long blade divided into segments, allowing the user to

"snap off" the dull edge, revealing a sharp one underneath. This

mechanism ensures the user can always access a sharp blade without needing a

separate sharpener or replacement blades.

Advantages of Snap-Off Blades

Convenience: The most evident

advantage is convenience. Maintaining a sharp edge without interrupting

workflow is a significant time-saver.

Cost-Effectiveness: Snap-off blades can be

more economical in the long run. Instead of buying new blades or sharpening

them frequently, you get multiple cutting edges on a single blade.

Safety: Regularly replacing blades can be hazardous.

Snap-off blades reduce the frequency of this process, potentially lowering the

risk of injury.

Consistent Sharpness: In professions where

precision is vital, having a consistently sharp blade is crucial. This design

ensures that a fresh edge is always available.

The Case Against Snap-Off Blades

However, it is also important to consider the disadvantages:

Structural Integrity: The fragmented design

of the Snap-Off blades is due to the fragility of their structural integrity,

which can pose a hazard. As they withstand a lower level of pressure than

conventional blades, they may not be suitable for some heavy-duty jobs.

Environmental Concerns: Frequent replacement

of the entire blade unit or improper recycling of broken blade segments can

pose an environmental problem.

Precision Limitations: For tasks that require

the utmost precision, the slight movement or flex of a snap-off blade could be

a disadvantage.

UTTIL's Approach to Snap-Off Blades

Examining how UTTIL, a brand synonymous with quality and innovation

in utility knives, approaches this technology sheds light on the practical

application of snap-off blades.

UTTIL recognises the convenience and efficiency of

snap-off blades, and its product range includes options that incorporate this

feature. However, it balances this with a commitment to durability and precision, ensuring that its snap-off blade products adhere to high

structural integrity standards. UTTIL's approach exemplifies how the

potential drawbacks of snap-off blades can be mitigated through thoughtful

design and high-quality materials.

Moreover, UTTIL's commitment to sustainability is evident in its

efforts to address the environmental impact of disposable blades. UTTIL

aims to reduce the ecological footprint of its products by promoting

responsible disposal while using more recyclable materials and new bioplastic technology.

In conclusion, snap-off blades offer a practical solution for many users of

utility knives, balancing convenience and functionality. They are particularly

suited for tasks that require frequent access to a sharp edge without the need

for heavy-duty cutting strength. However, it's essential to consider the type

of work you're doing and whether the benefits of snap-off blades align with

your needs.

In the realm of utility knives, there's no

one-size-fits-all solution. Snap-off blades may be the perfect answer for some,

while others might find traditional fixed or replaceable blades more suitable.

The decision ultimately rests on the user's requirements and the task.