A New Era in Snap-Off Knives: Mozart Blades' Gold (TiN) Coated Segments

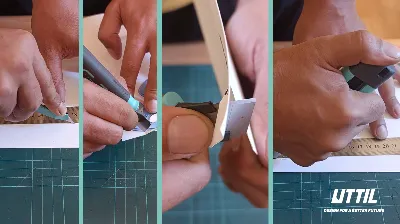

1. A Brief Overview of Snap-Off Technology

The snap-off design reduces inventory costs and

maintenance time by breaking the blade in one motion when it becomes dull,

resulting in a "new" blade. By combining UTTIL products with high-end

steel and modern TiN coating technology manufactured by Mozart Blades in

Solingen, UTTIL maximises cutting performance.

2. Scientific Basis of Titanium Nitride (TiN)

Coating

|

Feature |

Typical TiN Value |

Effect on Cutting Performance |

|

Microhardness |

2 400 - 2 800 HV |

Edge wear is delayed, and the snap-off segment lasts

longer. |

|

Coefficient of Friction |

0.4 - 0.7 (TiN/TiN, lean) |

Reduced heat build-up and adhesion risk when cutting

cardboard, plastic and rubber. |

|

Thermal Resistance |

Onset of oxidation ≈ 425 °C, use T ≈ 600 °C+ |

Sharpness is maintained in hot processes (e.g.

intensive PVC cutting). |

|

Coating Thickness |

2 - 4 µm (PVD) |

Blade geometry does not change; segment precision is

maintained. |

3. TiN Coated UTTIL Models

The entire UTTIL Aura Natura series—offering sustainability with a 40% wood chip + 60% PP composite body—and PTUK08‑EX, ELUK06, and ERUK06 models come with Mozart Blades TiN-coated blades as standard. This not only minimises the environmental footprint but also extends the blades' life.

Aura Natura: The

composite body recycles wood waste and reduces petroleum-based plastic by 40%.

Combined with the TiN coating, it reduces the number of blades, further

improving waste management. PLA series, on the other hand, dissolves

without harming nature with its compostable structure.

4. Sustainability and Occupational Safety

- Less

Waste: Long segment life reduces annual blade

consumption and metal scrap.

- Environmentally

Friendly Process: TiN is applied using the acid-free

PVD technique; chemical waste is minimal.

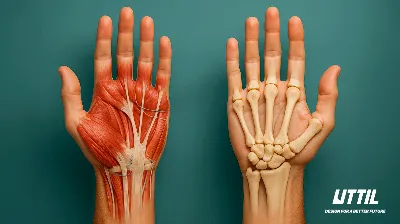

- Safety:

The segment stays sharp longer, relieving the user of excessive pressure

and reducing the risk of slipping and injury.

5. Conclusion

The Mozart Blades segments

with titanium-nitride (TiN) coating combine UTTIL's vision of "Design

for a better future" with tangible cutting performance. If you are

looking for longer life and less waste, check out the Aura Natura series and

our PTUK08-EX model:

Check out the website: https://uttil.com.tr/tr/aura-natura

Sharper in every segment, more sustainable in

every segment.