UTTIL's Holistic Strategy for Environmental Responsibility.

UTTIL is proactively working on multiple

fronts to tackle the environmental challenges of using plastics and producing

hand tools. Let us now summarise each of UTTIL's actions:

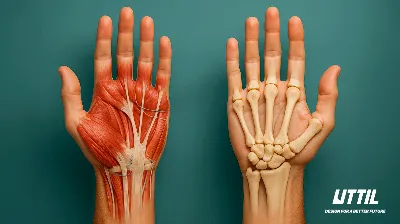

Material Innovation:

UTTIL's R&D efforts aim to discover new

materials or utilise found raw materials that can reduce the consumption of

petroleum-based plastics, which is a critical step in minimising the

environmental footprint of its products. UTTIL is actively trying to get

to the root of the plastic problem by using alternative materials.

Chemical

Structure:

UTTIL ensures that all products it uses are clean

enough to be in contact with food, regardless of their nature. When we say

contact with food, we mean using chemical materials that are not likely to

threaten human health within the framework of international regulations. All

raw materials used in UTTIL products are REACH and/or RoHS

certified by their nature. UTTIL makes the utmost effort to keep

chemicals that harm humans and nature away from all its products and production

processes, and all UTTIL products are 100% recyclable. Although UTTIL

makes maximum effort to ensure that its products do not contain substances such

as dioxins, phthalates, lead, chromium, nickel, etc., which have been declared

harmful, UTTIL continuously audits and regulates its manufacturing to

keep the chemicals required for production within the limits determined by the

regulations and even below these values when possible.

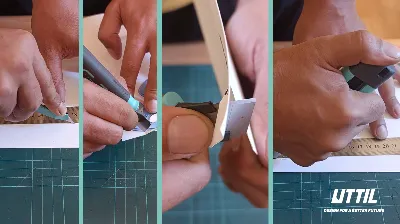

Product Design for Longevity:

UTTIL ensures customers do not need to replace them

frequently by designing tools for long-term use. This approach provides

economic benefits for the customer and reduces waste.

Recycling Program:

A recycling programme in its manufacturing

processes strongly indicates UTTIL's commitment to the circular economy.

This approach helps minimise waste by ensuring that production residues are

reused and recycled to the maximum extent without affecting quality standards.

Production Losses:

Plastic raw materials usually enter the

warehouse in lentil-sized pieces in sacks. These plastic particles can be

scattered around, no matter how much attention is paid during the processes,

from stacking in the warehouse, opening the pack for production, putting it in

and out of the drying oven, to loading it into the melting furnace. Reasons

such as rupture of the sack, loss of balance, leaving the mouth of the mixing

vessel open, loss of balance of the tray coming out of the drying oven, and

carelessness of the employee caused such scattering.

A large part of the industry includes these

losses in the wastage rates. Still, these scattered parts, which have lost

their quality of use by contamination, are swept or thrown into the factory

garden, waste sewerage, or, at best, the garbage heap. These scattered parts

also cause environmental pollution by mixing with nature and the ocean. On the

other hand, the enterprises that recycle the production waste recycle the waste

back to production by separating them into small pieces in various crushing

machines. During this process, some plastic turns into micro-plastics which

cannot be processed, and some turn into nano-plastics that even mix into the

air.

UTTIL has voluntarily taken measures

to prevent these leaks and training its workforce. By taking such steps, UTTIL

manages to avoid leaks of microplastics in the recycling area and to transfer

the raw material to the production area without scattering. All employees meticulously

monitor how to collect the raw material in case of possible spillage and how to

dispose of the collected unusable raw materials.

Consumer Education:

Educating consumers about the materials UTTIL uses in its products is the

key to raising sustainability awareness. In this way, customers can make more

informed decisions by considering the environmental impact of the products they

purchase.

Together,

these efforts show that UTTIL is committed to sustainable practices and

is an example of how companies can incorporate sustainability into their

business models.

By working on innovative use of materials,

longer product lifetime, recycling initiatives and consumer education, UTTIL continues

its endeavour to take a comprehensive and informed approach to the problem of

plastic waste from many angles.