UTTIL's Role in Supporting Circular Economy in Hand Tool Manufacturing

UTTIL's Role in Supporting Circular Economy in Hand Tool

Manufacturing

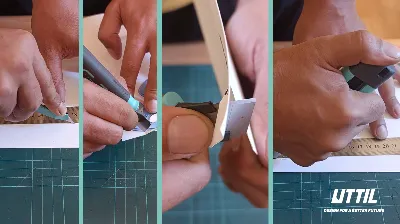

In today's world, the circular economy is a model for

sustainable production that promotes environmental stewardship and economic

flexibility. UTTIL is a company in the hand tool industry that is

developing sustainable practices.

Adopting Circular Economy: The circular economy aims to

eliminate waste and promote the continuous use of resources by closing energy

and material cycles. This goal can be achieved through sustainable material

choices, long-life design, maintenance, repair, reuse, remanufacture, refurbishment

and recycling. UTTIL creates structural adjustments in its production

and products to support the circular economy:

Sustainable Material Choices: UTTIL has taken

significant steps in sourcing sustainable materials that are durable and

environmentally friendly. Using recycled metals and biodegradable polymers in

the hand tools it manufactures ensures that each product's environmental impact

is reduced. These materials are easily recyclable. However, UTTIL,

sensitive to preventing plastic pollution, has a severe policy to minimise the

petroleum-based plastics used in its products. Within the framework of this

policy, it closely follows the developments in the material world and has

started to use non-permanent, durable bioplastics in its products. On the other

hand, by using natural fibres, it has developed products that can reduce the

amount of petroleum-based plastics used in production by up to 40%. UTTIL

aims to withdraw petroleum-based plastics from output at the highest level or

even entirely by closely following the developing materials.

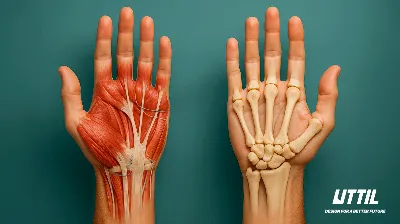

Product Design and Longevity: Durability is at the centre

of UTTIL's product design philosophy. Each tool is designed to last a

long time, reducing the need for frequent replacement and thus reducing waste. UTTIL

also makes every improvement necessary to ensure that all materials it uses are

recyclable and do not harm people and nature. Hence, it aims to recycle the

products that have completed their service life so that their materials can be

reused.

Efficient Production Processes: UTTIL uses production

techniques that minimise waste. Its facilities are optimised for energy

efficiency, and waste materials from production are recycled for reuse. This

approach significantly reduces the environmental impact of production

processes.

Efficient Resource Management: UTTIL takes a proactive

approach to managing production waste, ensuring that sustainability is

interwoven into every aspect of its production processes. UTTIL has

implemented a robust system whereby production residues are either reintegrated

into the production cycle or disposed of in an environmentally sound manner.

This method minimises waste while at the same time ensuring that the quality of

hand tools is not compromised. By recycling materials at source, UTTIL

reduces the need for new raw materials and lowers its overall environmental

impact. This in-house recycling method emphasises UTTIL's commitment to

circular economy principles and demonstrates how industrial waste management

can be both sustainable and economically viable.

Consumer Engagement and Education: Recognising that

consumer behaviour is critical to the circular economy, UTTIL prepares

for and invests in comprehensive consumer education programmes. These

initiatives provide consumers with a straightforward education on proper tool

maintenance, recycling processes, plastic pollution, and the circular economy's

benefits.

Impact on Consumers and the Environment: For consumers, UTTIL's commitment to a circular economy means cost-effective, high-quality products compatible with environmentally conscious values throughout their life cycle. By reducing waste, lowering carbon emissions and conserving resources, UTTIL is helping to lighten the ecological footprint of the hand tool industry.

Integrating circular economy principles into

production is not a trend but is necessary to move forward. Rather than being a

benchmark, UTTIL's proactive behaviour demonstrates the tangible

benefits of such practices. For other companies looking to make a difference, UTTIL's

model offers a replicable blueprint for success in sustainable manufacturing.