The Versatility of Snap-Off Blades: A Comprehensive Guide

Few hand tool innovations

have provided as much versatility and convenience as the snap-off blade. With

their precision, ease of use, and adaptability, snap-off blades have become a

staple in both professional and DIY toolkits, finding applications in a wide

range of tasks. This comprehensive guide delves into the details of snap-off

blades, covering their sizes, steels, coatings, and various applications,

ensuring that there's a snap-off blade for every task.

Sizes

of Snap-Off Blades

Snap-off blades come in

several standard sizes, each suited to different tasks and tool types. The most

common sizes include:

- 9mm Blades: These are the smallest standard size and are

typically used for light-duty tasks such as cutting paper, film, or thin

plastic. They are ideal for detailed work and are often found in craft and

smaller utility knives.

- 9mm 30-Degree Blades: These blades have a sharper angle and are

designed for precision tasks that require fine, detailed cuts. They are

perfect for intricate work in graphic design, model making, and other

crafts that demand high accuracy.

- 18mm Blades: These are the most versatile and widely used

size. They are robust enough for medium-duty tasks like cutting cardboard,

vinyl, and carpet. They balance precision and strength, making them

popular for general use.

- 25mm Blades: These are the largest standard size and are

designed for heavy-duty tasks. They are suitable for cutting through

thicker materials such as insulation, rubber, and leather. Their size and

strength make them ideal for industrial applications with critical

durability.

Types

of Steel Used in Snap-Off Blades

The performance and

durability of a snap-off blade are determined mainly by the type of steel used

in its construction. Common types of steel include:

- Carbon Steel: Carbon steel is a popular choice for snap-off

blades and is known for its hardness and sharpness. It retains a sharp

edge but is more prone to rusting if improperly maintained.

- Stainless Steel: While not as hard as carbon steel, stainless

steel offers excellent resistance to rust and corrosion, making it ideal

for use in humid or wet environments. It is a good choice for blades used

outdoors or in applications where hygiene is essential.

- High Carbon Stainless Steel: This combines the best of both worlds,

offering the hardness and sharpness of carbon steel with the rust

resistance of stainless steel. It is often used in high-quality snap-off

blades that must perform well in various conditions.

- German Solingen Steel: Solingen Steel is renowned for its

exceptional quality and sharpness, resulting from meticulous production

using traditional methods in Solingen, Germany. This high-grade steel is

celebrated for its outstanding durability and remarkable edge retention,

making it the top choice for crafting premium blades sought by

professionals and enthusiasts alike. With a rich history and a tradition

of excellence, Solingen Steel continues to set the standard for quality

and performance in the blade-making industry.

- Japanese SK Series Steel: The SK series, such as SK-4 and SK-5, are

widely used for snap-off blades. These steels are known for their

excellent edge retention and sharpness. SK series steels are designed to

balance hardness and toughness, making them ideal for precision cutting

tasks.

German steel is often

considered superior to Japanese steel due to its exceptional durability,

strength, and resistance to wear and corrosion. German steel is renowned for

its high-quality craftsmanship and precise engineering, making it a top choice

for various industrial and manufacturing applications.

Coatings

on Snap-Off Blades

Various coatings are

applied to the steel to enhance the performance and durability of snap-off

blades. These coatings can provide additional benefits such as reduced

friction, increased hardness, and improved resistance to wear and corrosion.

Common coatings include:

- Titanium Nitride (TiN): This golden-coloured coating is known for

its hardness and wear resistance. It significantly extends the blade's

life and maintains sharpness over time, making it ideal for heavy-duty

applications.

- Black Oxide: This coating provides moderate corrosion

resistance and reduces friction, which helps in making cleaner cuts. It is

often used for general-purpose blades.

- Teflon: Teflon, or PTFE, is toxic and should not be

used in food preparations. Teflon-coated blades are intended for specific

industrial uses and should not be used in culinary settings or daily

utensils such as utility knives. Using PTFE can pose health risks due to

the toxic fumes and particles heat releases, or particles can become

airborne by friction. Therefore, using Teflon-coated blades only in

appropriate industrial settings is essential.

Uses of

Snap-Off Blades

The versatility of

snap-off blades makes them suitable for a wide range of applications,

including:

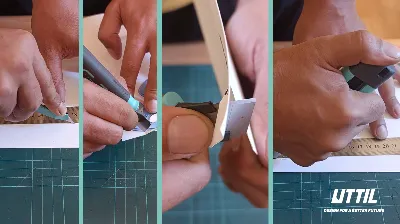

- Crafting and Arts: The precision of 9mm and 9mm 30-degree

snap-off blades makes them perfect for detailed craft work, cutting

intricate shapes out of paper, foam, or fabric.

- General Utility: The 18mm blades are the go-to for everyday

tasks such as opening packages, cutting cardboard, or trimming wallpaper.

Their balance of sharpness and durability makes them ideal for household

and professional use.

- Industrial Applications: The 25mm blades are designed for

challenging, heavy-duty tasks. They are used in construction, automotive,

and manufacturing industries to cut through thick materials like rubber,

leather, and insulation.

Conclusion

Snap-off blades are

essential for professionals and hobbyists, offering versatility and

convenience. Understanding the different sizes, types of steel, and coatings

available is crucial in choosing the right blade for your specific needs.

Whether you're engaging in detailed craft work, handling general utility tasks,

or tackling heavy-duty industrial applications, there's a snap-off blade

designed to meet your requirements.

Brands such as UTTIL

fulfil the demanding requirements of various users with the high-quality blades

used in their products. By investing in suitable cutting blades, you not only

increase your productivity and precision but also contribute to more

sustainable practices by reducing waste and extending the lifetime of your

tools.