Sealing the Gaps: A Guide to Selecting and Using Sealants Effectively

As a UTTIL

expert, I'm here to guide you through the ins and outs of selecting and using

sealants for all your DIY projects. UTTIL is a trusted brand in the DIY industry,

known for its high-quality tools and materials. Whether weatherproofing your

windows or caulking a bathtub, the right caulking gun is as crucial as the

sealant. UTTIL's range of caulking guns is designed with the DIY

enthusiast in mind, offering ease of use, precision, and durability.

Understanding Sealants

Sealants are

versatile tools in construction and home repair. They fill gaps, seams, and

joints to prevent water, air, and environmental toxins from entering or

escaping. When choosing a sealant, consider the location of the application,

exposure to elements, and material compatibility. Remember, each sealant

has unique benefits, so you can confidently choose the one that best suits your

project.

Silicone

Sealants:

Silicone

sealants are renowned for their flexibility and water resistance, making them

an ideal choice for areas exposed to moisture. Here's why they're a go-to

option for wet environments:

Durability: They withstand temperature

changes without cracking or drying out.

Waterproofing: Perfect for use in bathrooms,

kitchens, and outdoor applications due to excellent waterproof properties.

Non-Paintable: Silicone sealants typically

cannot be painted over, which is crucial for a project's finished look.

Adhesion: They adhere well to non-porous

surfaces, making them suitable for sealing around bathtubs, sinks, and tiles.

Acrylic

Sealants:

Acrylic

sealants, often used for indoor projects, offer a different set of advantages:

Paint

Compatibility: These

sealants can be painted, allowing a seamless blend with the surrounding

surface.

Ease

of Use: They

are generally easier to apply and smooth out than silicone, and they are

user-friendly, even for beginners.

Versatility: Ideal for filling cracks in

window frames, baseboards, and doors.

Cost-Effective: Typically less expensive than

silicone, making them a budget-friendly option for large projects.

Polyurethane

Sealants:

For tasks

requiring a stronger bond and durability, polyurethane sealants are a robust

option:

Strength: They create a strong seal that

can bear weight and handle movement, perfect for areas subject to foot traffic

or load-bearing joints.

Flexibility: Retains elasticity over time,

critical for materials that expand and contract.

Chemical

Resistance: Resistant

to chemicals, oil, and gasoline, making them suitable for garages and

driveways.

Butyl

Sealants:

Butyl

sealants are rubber-based and offer unique properties:

Adhesive

Strength: They

have excellent adhesion to most materials, including metal and concrete.

Water

Resistance:

Exceptional for sealing outdoor structures like gutters and roofs.

Selecting the Right Sealant

Consider

the Application: The

sealant's location is crucial—different environments require different sealant

properties.

Material

Compatibility: Make

sure the sealant is compatible with the surface materials.

Curing

Time: Check

if the area needs to be used soon after application.

UTTIL's range of caulking guns supports

these various sealants, providing the tools to apply them precisely and

effectively. Always refer to the manufacturer's instructions for the best

application results and ensure the longevity of your sealant.

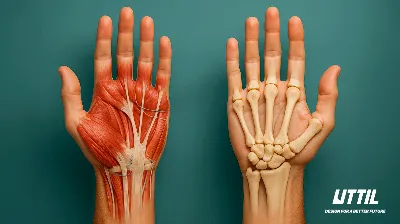

Choosing the Right Caulking Gun

UTTIL's range

of caulking guns is engineered with the DIY enthusiast in mind. Here's what

sets them apart:

Ease

of Use: A

caulking gun should be easy to handle, and UTTIL guns provide a

comfortable grip that reduces hand fatigue, which is essential when

working on longer projects. Rest assured, with UTTIL's range of caulking

guns, you'll find the tool that makes your DIY experience a breeze.

Precision: With smooth pressure systems, UTTIL

caulking guns allow for a consistent bead of sealant, which is essential

for the seal's appearance and effectiveness.

Durability: UTTIL caulking guns are

designed for longevity and are constructed from robust materials so that you

won't need a replacement after just a few uses.

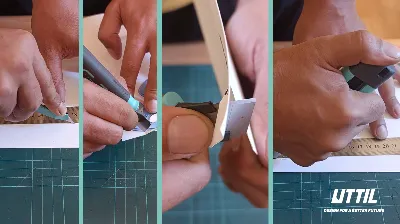

Preparing for the Job

Before you

start caulking, surface preparation is critical. Ensure the area is clean, dry,

and old sealant, grease, or dirt-free. For more profound gaps, use a backer rod

to provide a better base for the sealant. This means removing any old sealant

or paint, cleaning the surface with a mild detergent, and allowing it to dry

completely. For deeper gaps, insert a backer rod to ensure the sealant adheres appropriately

and fills the gap.

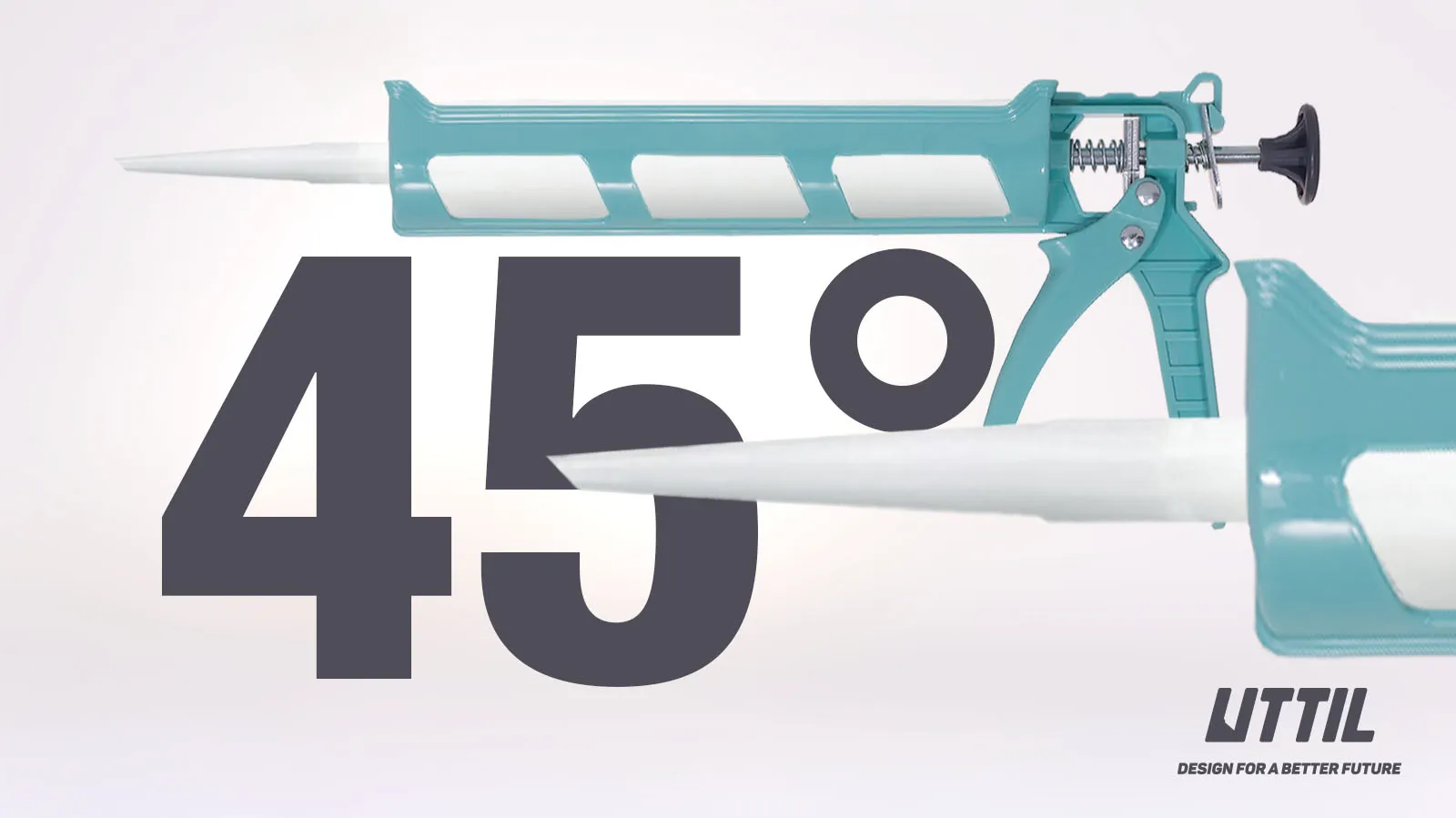

Using Your Caulking Gun

Cut the tip

of the sealant tube at a 45-degree angle. This allows you to work the gun at a

45-degree angle to the gap, the recommended angle for most caulking tasks.

When sealing,

start with the innermost corner and work your way outwards. Maintain a steady

hand and even pressure on the trigger. If you make a mistake, don't worry –

most fresh sealants can be wiped away cleanly, allowing you to try again. Hold a caulking gun at a 45-degree angle to the surface and apply

steady pressure to the trigger. Move the gun along the gap in a smooth,

continuous motion, ensuring the sealant fills the gap. If you need

to stop, release the pressure on the trigger to prevent excess sealant from

oozing.

Finishing Touches

Once the

sealant is applied, you can smooth it out with a caulking tool or even a damp

finger, depending on the type of sealant. Remember, silicone sealants will not

clean up with water, so have some mineral spirits handy for cleanup.

Aftercare

After you've finished your project, cleaning and storing your UTTIL caulking gun is straightforward. Pull back the plunger and remove the sealant tube. Clean any excess sealant from the gun with a cloth, and it's ready for your next DIY adventure.

With the right UTTIL tools and some

know-how, sealing gaps becomes a simple, satisfying task that significantly

contributes to your home's maintenance and energy efficiency. Happy caulking!

If you encounter any issues during the caulking process, such as the sealant

not adhering properly or the bead not forming correctly, refer to our

troubleshooting guide for solutions.