PLA: The Compostable Plastic Revolutionizing UTTIL's PAUK06 and PRUK06 Mode

One eco-friendly star stands out in the

ever-evolving world of materials science: Polylactic Acid (PLA). This

compostable plastic is transforming industries, particularly in sustainable

manufacturing. UTTIL's adoption of PLA in its PAUK06 and PRUK06

models exemplifies how this material can bring about a significant

environmental shift while maintaining the quality and functionality of hand

tools. This blog post explores the advantages of PLA and how UTTIL is

leveraging it to create a more sustainable future.

1. Understanding PLA: The Basics

PLA is a type of bioplastic derived from

renewable resources like cornstarch or sugarcane. It stands out for being

compostable under industrial composting conditions. This property makes PLA a

game-changer in the world of plastics, offering a viable solution to the global

challenge of plastic waste.

2. The Compostable Advantage

The most notable advantage of PLA is its

compostability. Unlike traditional plastics, which take hundreds of years to

decompose, PLA can break down into natural elements in a composting facility

within a few months. This rapid decomposition significantly reduces landfill

waste and the environmental impact associated with plastic disposal.

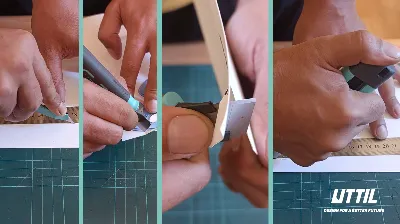

3. PLA in UTTIL's PAUK06 and PRUK06 Models

UTTIL's

use of PLA in the PAUK06 and PRUK06 models demonstrates the

practical application possibilities of this material in hand tools. UTTIL

can ensure that the parts of the tools it produces with its own PLA formula are

durable, efficient, and environmentally friendly.

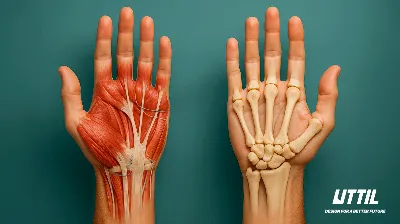

4. Why PLA is an Ideal Choice for Hand Tools

Durability and Strength: Despite being compostable, PLA exhibits a high level of strength and

durability, making it suitable for the rigorous demands of hand tools.

Safety:

PLA is free from toxins like Bisphenol-A (BPA), making UTTIL tools safer

for users and the environment.

Lightweight Nature:

PLA's lightweight properties contribute to the ergonomic design of UTTIL's

tools, enhancing user comfort and usability.

5. UTTIL's Commitment to Sustainability

By choosing PLA, UTTIL reaffirms its

commitment to sustainability. This choice reflects a conscious effort to reduce

environmental impact and promote renewable materials in manufacturing.

6. The Production Process of PLA in UTTIL Tools

UTTIL's

production process for integrating PLA into its tools is carefully managed to

ensure the material's environmental benefits are fully realised. From sourcing

the raw material to the final product, UTTIL focuses on sustainability

and quality.

7. Consumer Benefits of Using PLA-Based Tools

Consumers who choose UTTIL's PLA-based

tools benefit from their functionality and contribute to a more sustainable

world. Consumers support eco-friendly practices and reduce their ecological

footprint by opting for products made with compostable plastics.

8. The Future of PLA in Tool Manufacturing

PLA's role in tool manufacturing is just

beginning. As technology advances, its applications are expected to broaden,

paving the way for more innovative and sustainable products.

9. UTTIL: Pioneering the Use of PLA in Hand

Tools

UTTIL's

integration of PLA in models like the PAUK06 and PRUK06 is just

the start. The company is dedicated to exploring new ways to incorporate

eco-friendly materials into its product line, leading the charge towards a more

sustainable future in tool manufacturing.

PLA represents a hopeful and practical step

towards addressing the plastic waste problem. UTTIL's adoption of PLA in

its hand tools demonstrates that it is possible to balance product quality with

environmental responsibility. As consumers, having reliable and efficient tools

by choosing products like PAUK06 and PRUK06 means participating

in a more significant movement towards sustainability.

A more detailed blog post about PAUK06 and PRUK06:

https://uttil.com.tr/en/reinventing-hand-tool-standards-with-pauk06-and-pruk06