New Frontiers in Plastic Recycling and UTTIL's Commitment to Environmental Management

As the

global community becomes increasingly aware of the environmental impact of

plastic waste, the search for more efficient and less harmful recycling

technologies has become even more urgent. This article examines the latest

developments in plastics recycling, assesses the environmental risks associated

with conventional recycling facilities, and outlines how UTTIL is leading the

way regarding ecological responsibility in the industry.

The Cutting Edge of Plastic Recycling Technologies

The

limitations of conventional mechanical recycling, where plastics are melted

down to form new materials, have spurred innovation in chemical recycling

technologies. These exciting emerging methods aim to break down plastics to

their molecular level, offering the potential for infinite recyclability

without degrading quality and providing a hopeful future for plastic recycling.

Pyrolysis: This process involves heating

plastics without oxygen to break them down into synthetic crude oil, which can

then be used to produce new plastics or as an alternative fuel source.

Enzymatic Recycling: Researchers have engineered

enzymes capable of breaking down PET plastics into their original monomers,

which can then be reused to manufacture new, virgin PET plastics.

Solvent-Based Purification: This

method dissolves plastic waste in solvents, enabling the extraction and

purification of polymers, which can be reused in high-quality applications.

Environmental Concerns of Recycling Facilities

Despite

the promise of these technologies, traditional recycling facilities, especially

those relying on mechanical processes, pose significant environmental risks.

The emissions from melting plastics contribute to air pollution, and using

water in cleaning processes can contaminate water. Moreover, the residues and

non-recyclable fractions often end up in landfills, negating the benefits of

recycling.

Chemical

recycling, while innovative, has an environmental footprint. Processes like pyrolysis, which consumes a lot of energy, and solvent-based purification use potentially hazardous chemicals, raising concerns about their

sustainability and safety.

What Happens To What Cannot Be Recycled?

The most

daunting challenge in plastic recycling is the intricate nature of plastic

types and chemical compositions. Even plastics of the same quality can create

different chemical compositions and mechanical values when mixed with

colourants and additives. This complexity makes it nearly impossible to sort

plastics for recycling, which demands high-tech and costly

investments. Furthermore, these sorting processes pose significant

environmental hazards. The plastic recycling rate remains alarmingly low even in countries with the most advanced sorting technologies, such as Germany. Germany, with its existing high technologies and consumer education, can

only collect 55 per cent of its plastic waste for recycling and convert about

35 per cent of it into usable products. The rest is incinerated as waste.

Almost all disposable packaging waste is non-recyclable due to food and oils, prints, metalised coatings, compositing materials with paper, plastic and metal sheets, etc. Moreover, recyclable products such as paper are prevented from recycling through plastic surface coatings or composite applications such as

beverage boxes.

Clear

restrictions and regulations on single-use packaging plastics and disposable

products should be introduced. In particular, packaging used to transport

liquids should be banned immediately, and the use of plastic-coated paper

should be prevented.

Another

serious plastic pollution source is the textile/fashion sector; synthetic yarns (nylons, polyesters, and various elastomers used instead of rubber) used here damage nature by scattering micro/nano plastic particles in every wash

and entering the human body through the skin.

Plastics

used in maritime transport and fishing are significant contributors to the rapid and

intensive pollution of our seas and oceans, posing a grave threat to underwater

life. The current international regulations regarding this situation are inadequate, underscoring the urgent need for global action. This is

not just an environmental issue but a collective

UTTIL's Approach to Sustainable Recycling

In

response to these challenges, UTTIL is at the forefront of integrating

environmental responsibility into every facet of its operations. Recognising

that the solution to plastic pollution is multifaceted, UTTIL has

adopted a holistic approach:

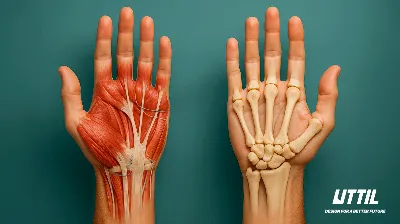

Material Innovation: UTTIL invests in

research and development to create durable products from bio-based

materials, reducing reliance on virgin plastics.

Partnerships for Advanced Recycling: Understanding the limitations of traditional recycling, UTTIL partners with

innovators in chemical recycling to ensure their products are compatible with

the most advanced recycling technologies, aiming for a truly circular economy.

Consumer Education: UTTIL is committed to

educating consumers about proper disposal and recycling practices, empowering

them to be part of the solution.

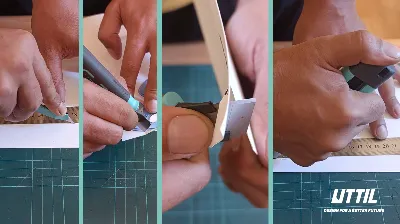

Reducing Production Waste: UTTIL minimises production waste by optimising manufacturing processes and

ensuring that scrap materials are recycled back into the production cycle or

responsibly disposed of.

Environmental Advocacy: In addition to its

operational practices, UTTIL advocates for policy changes and industry

standards that promote sustainability and environmental stewardship.

The

journey towards sustainable plastic recycling is complex, requiring

technological innovation and a fundamental shift in how we produce, use, and

dispose of plastics. While the latest recycling technologies offer promising

paths forward, their environmental impact must be carefully managed.![]()

![]()

UTTIL is an excellent example of a

company proactively taking environmental responsibility. They are

achieving this by innovating their materials and advocating for systemic

change. This approach shows how companies can lead by example and help

transition towards a more sustainable and less polluting recycling industry. UTTIL

is prioritising the planet by embracing innovation. By doing so, they are

helping to pave the way for a future where recycling contributes to the health

of our environment rather than its detriment.