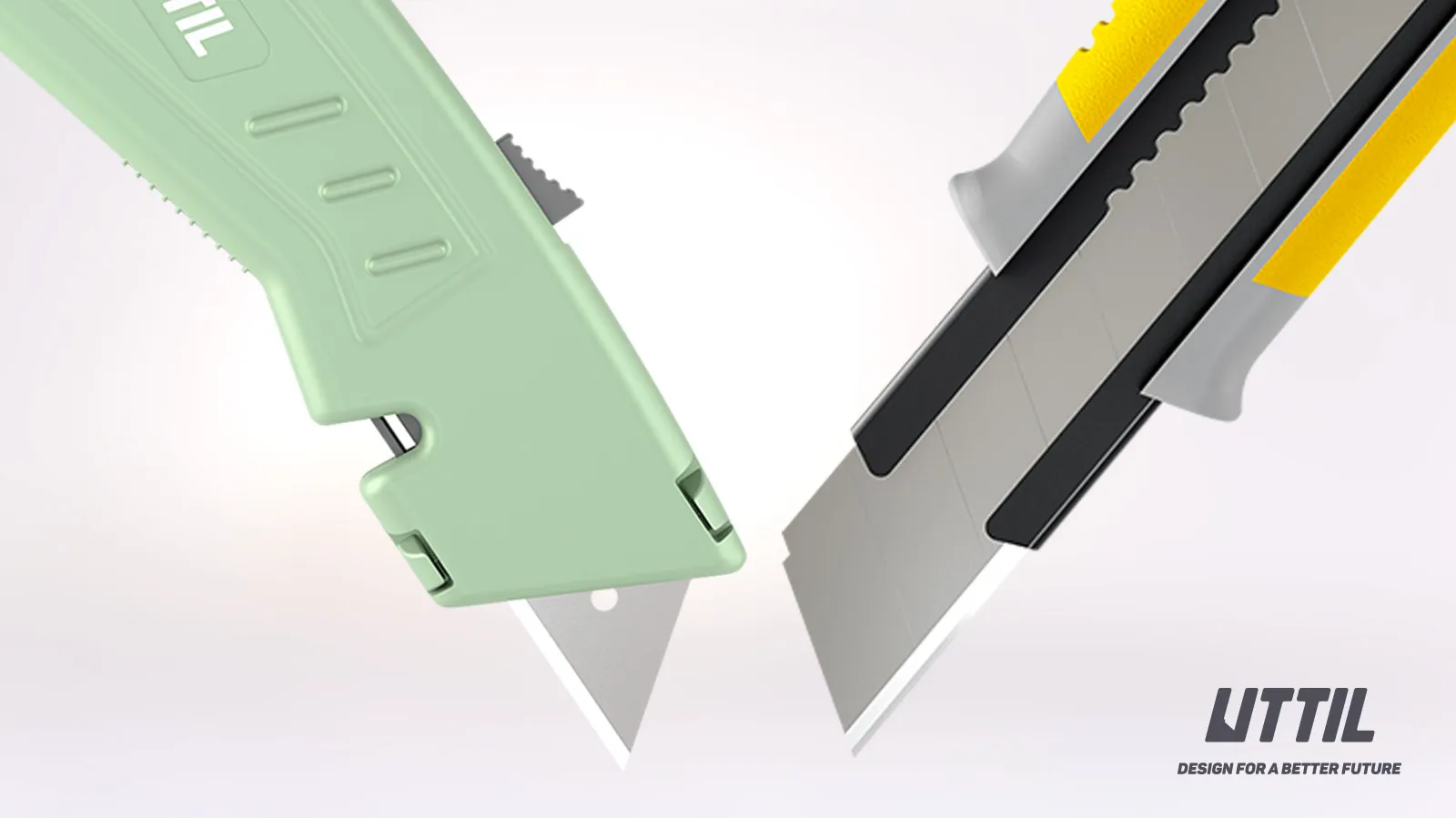

Choosing the Right Blade for the Job: Snap-Off vs. Trapezoidal Blades

The blade is where the magic happens

in utility knives. The two most popular blades are snap-off and trapezoidal

blades, which are preferred according to the area of use.

Flexibility of

Use of Snap-Off Knives

With

their long, segmented design, clip-and-throw knives offer a unique advantage:

as the edge dulls, the user can snap off the tip to reveal a new, sharp piece.

This function makes snap-off blades attractive for jobs that require

uninterrupted sharpness.

The Advantages of

Snap-Off Knives:

Continuous Sharpness: Breaking

off a blunt segment for a new edge reduces downtime, increasing productivity,

especially in fast-paced environments.

Cost Effectiveness: Thanks to

their multi-segment design, these blades potentially outlast their counterparts

in situations where the job doesn't tax the blade's strength too much.

Versatility: Snap-off

blades are versatile and ideal for precision tasks in the graphic design, craft

and light packaging industries.

Limitations:

Structural Integrity: These

blades' segmented nature means they may need to hold up better on heavy-duty

jobs. The fact that they can only work correctly by ejecting one segment at a

time creates difficulties when deeper and more controlled cutting is required.

They may not be suitable for work that can be done with more than one segment

sticking out and may break under load if misused.

Waste Generation: Each

breakout operation generates waste. This can lead to increased waste in

high-volume environments. However, blades made from a long life and suitable

steels (Solingen steels, Japanese SK5, SK2, etc.) can minimise this effect as

they can cut 10 to 50 times more than blades from ordinary spring steel (such

as CK75).

Trapezoidal

Blades: Robust Performance,

Trapezoidal

blades are the workhorse of utility knives. Their thick and robust design

allows for heavy-duty use, cutting through more rigid materials quickly. Unlike

snap-on blades, trapezoidal blades are replaced rather than adjusted when

dulled, ensuring maximum durability for every task.

Advantages

of Trapezoidal Blades:

Durability: These

blades can handle rigid materials, from stiff cardboard to flooring, because

they are designed for heavy-duty use. They outperform even CK75-grade steel for

cuts such as paper and cardboard. However, blades made from better steels

should be preferred if cutting more demanding materials other than paper and

cardboard.

Safety: Trapezoidal

blades are robust and have less risk of breakage during use. This makes it a

safer knife class for heavy-duty applications.

Precision: Despite

their robustness, trapezoidal blades do not compromise precision, making them

suitable for detailed jobs requiring more power.

Limitations:

Sharpness Maintenance: Unlike

folding blades, a trapezoidal blade can be used on both sides, front and back,

without losing its sharpness. Blunted blades are usually used with a blade

carrier mechanism in a screw body, so blade refresh time is longer.

Less Flexibility: Lack of

immediate access to a new edge means that users are likely to work with a

duller blade for longer than is ideal, potentially compromising cutting

efficiency, quality and safety.

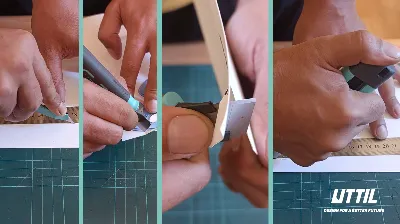

Best Uses in

Industrial and Creative Applications

Snap-Off knives excel in environments

where precision and the ability to maintain a consistently sharp edge outweigh

the need for coarse cutting power. Graphic designers, artists and artisans find

these blades ideal for precise and detailed work.

Trapezoidal

Blades are better suited for construction, manufacturing and heavy-duty DIY

projects. Thanks to their strength and durability, they are favoured for

cutting hard materials where precision is required. However, the quality of the

blade must be selected strictly according to the task to be performed.

Heavy-duty tasks require a blade that can withstand severe pressure.

Conclusion

The

choice between snap-off and trapezoidal blades depends on the specific

requirements of the task at hand. The snap-off blades are unrivalled for those prioritising

flexibility and sustained sharpness without needing heavy-duty cutting power.

In contrast, trapezoidal blades excel in tasks requiring durability and the

ability to cut through more rigid materials with precision and safety.

Understanding

the strengths and limitations of each blade type enables users to maximise

their productivity, safety and the quality of their work, whether in industrial

environments or creative projects. As with any tool, the right choice

enhances the craft and the pleasure of working.