A Promising Innovation in Plastic Recycling.

Hello,

friends of the environment! Let's talk about a topic that's close to our

hearts: recycling. We all know the importance of managing plastic waste, and

now there's a bright spot on the horizon that's worth sharing.

Scientists

at the US Department of Energy's Oak Ridge National Laboratory have been busy

bees, working on a new catalytic process that gives mixed plastics a new lease

of life. Their latest study, in the journal published by Materials Horizons, is

not just about sorting and recycling. It's about transforming these plastics into

their original forms, known as monomers, with an eye on precision and

environmental benefits.

This isn't

just a small step; it's a giant leap in reducing our carbon footprint. The

process could cut greenhouse gas emissions by up to 95%, slash energy inputs by

up to 94%, and reduce fossil fuel consumption by up to 96%. That's a breath of

fresh air for our planet!

Tomonori

Saito, the synthetic polymer chemist leading the charge, explains, "We've

developed a specialised organocatalyst. This isn't your everyday chemical. It's

a compound that's adept at converting mixed plastic waste into valuable

monomers, which can then be repurposed to create high-quality plastics and

other materials."

This

innovative approach could revolutionise how we recycle, saving an estimated 3.5

billion barrels of oil each year if adopted worldwide. That's a lot of energy

conserved for future generations!

Now, let's

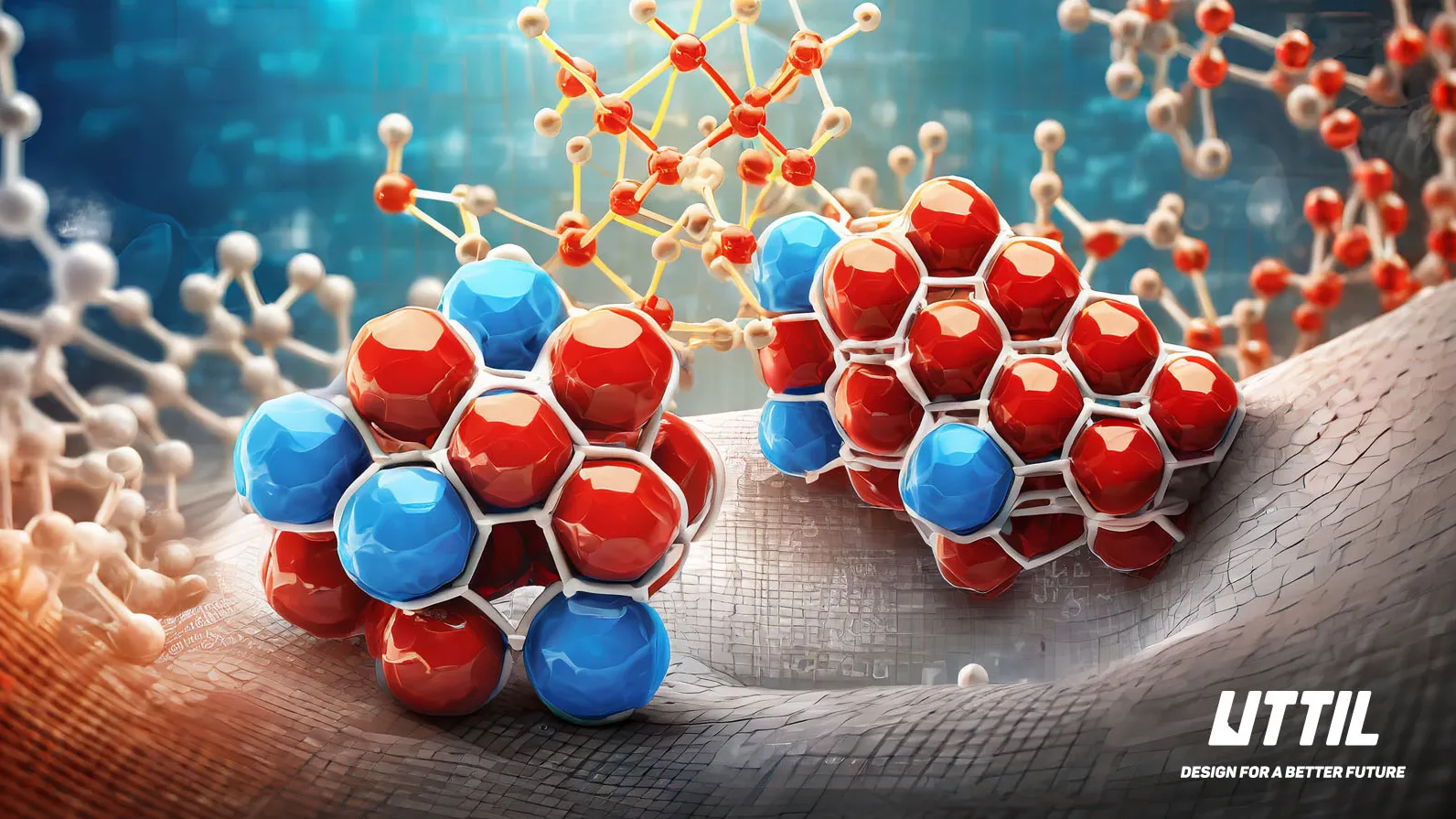

dive a little deeper into the science. The team used a technique called

small-angle neutron scattering at ORNL’s Spallation Neutron Source. This method

is like a super-microscope that scatters neutrons to reveal the structure of

materials down to the tiniest detail. It confirmed that the organocatalyst effectively

broke the waste plastics into monomers.

What's neat

is how the organocatalyst works its magic at different temperatures to break

down various plastics. Polycarbonates, for instance, are deconstructed at 130°

C, while polyurethanes need a bit more heat at 160° C. Polyethylene

terephthalates and polyamides follow suit at 180° C and 210° C, respectively.

This temperature-controlled process means that each type of monomer can be

recovered separately and reused, while other materials are left untouched for

further recovery.

The

environmental perks of this method are clear. It moves away from harsh

chemicals traditionally used for breaking down polymers and offers a more

selective, stable, and safer alternative. Plus, its efficiency against multiple

types of plastics makes it a strong candidate for tackling the complex mix of

materials we find in today's consumer products.

In

conclusion, this research is a collaborative triumph, with contributions from

various departments within ORNL and the University of Virginia, all under the

umbrella of the US Department of Energy's support.

At UTTIL, we're thrilled by the pioneering research coming out of ORNL. This breakthrough represents a significant leap forward in the circular economy, a concept that UTTIL deeply invests in. The prospect of turning plastic waste into reusable monomers not only fuels our enthusiasm for innovation but also reinforces our commitment to responsible manufacturing and consumption.

As we look to the future, this breakthrough gives us hope. It's a testament to the power of innovation and the potential for science to lead the way in creating a more sustainable world. Let's keep the conversation going and the ideas flowing for the sake of our beautiful planet.